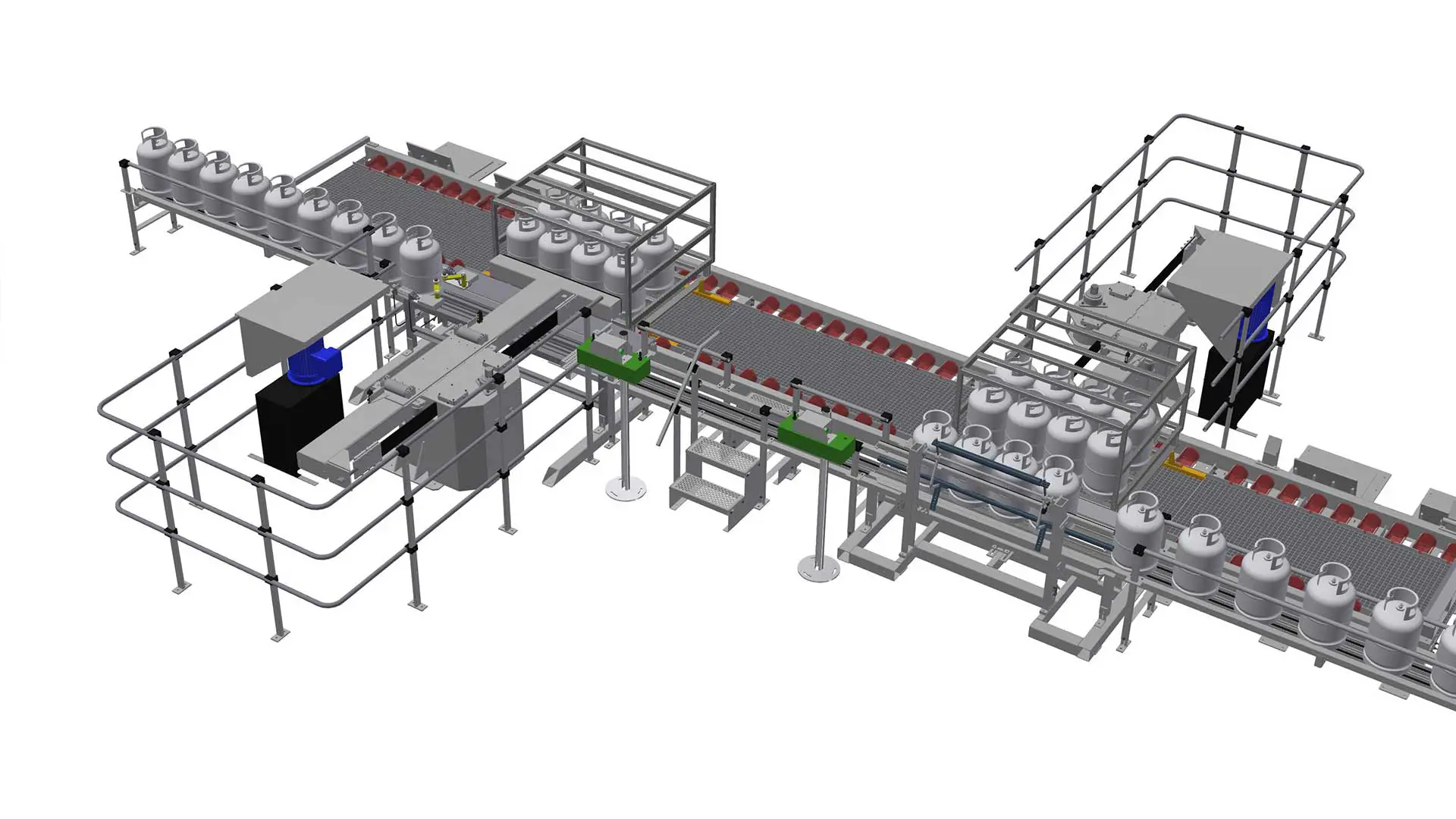

Handling and transport equipment

The manually controlled palletiser LPM is a modular system designed for loading/unloading operations of cylinders in pallets. It is an efficient way to get cylinders in pallets in/out to/from a filling plant.

The palletiser is loaded with pallets using forklifts. After loading pallets with empty cylinders onto the inlet module, all processes (pallet transport, pallet emptying/unloading and pallet filling/loading) are manually controlled. Finally the pallets are moved to the outlet module, the last module on the palletiser. The pallets in the outlet module contain filled cylinders, ready to be unloaded by a forklift. Depending on the customer’s requirements, the palletiser can be configured for only loading or only unloading of cylinders in pallets.

Benefits

Safety and profits

- Use of pallets reduces the human involvement in transferring cylinders to/from trucks or storage from/to filling.

- Optimised logistics (cylinder storage space and cylinder in/out traffic on a filling plant) ensures high operational safety (see logistics and safety illustration).

- More safe cylinder handling and transportation with pallets minimise cylinder damages (preserving cylinder quality ensures end-user safety). Also, maintaining the cylinder quality reduces cylinder repair costs and increases operational reliability (e.g. damaged cylinders can cause damages to filling equipment).

Maximum production uptime

- Automatic operation stops (e.g. low compressed air pressure) prevent process errors and assist in quick restarting.

- Robustly designed and protected (e.g. galvanised) for long-lasting performance.

Optimised production

- Highly efficient cylinder handling in pallets is essential for high-speed production.