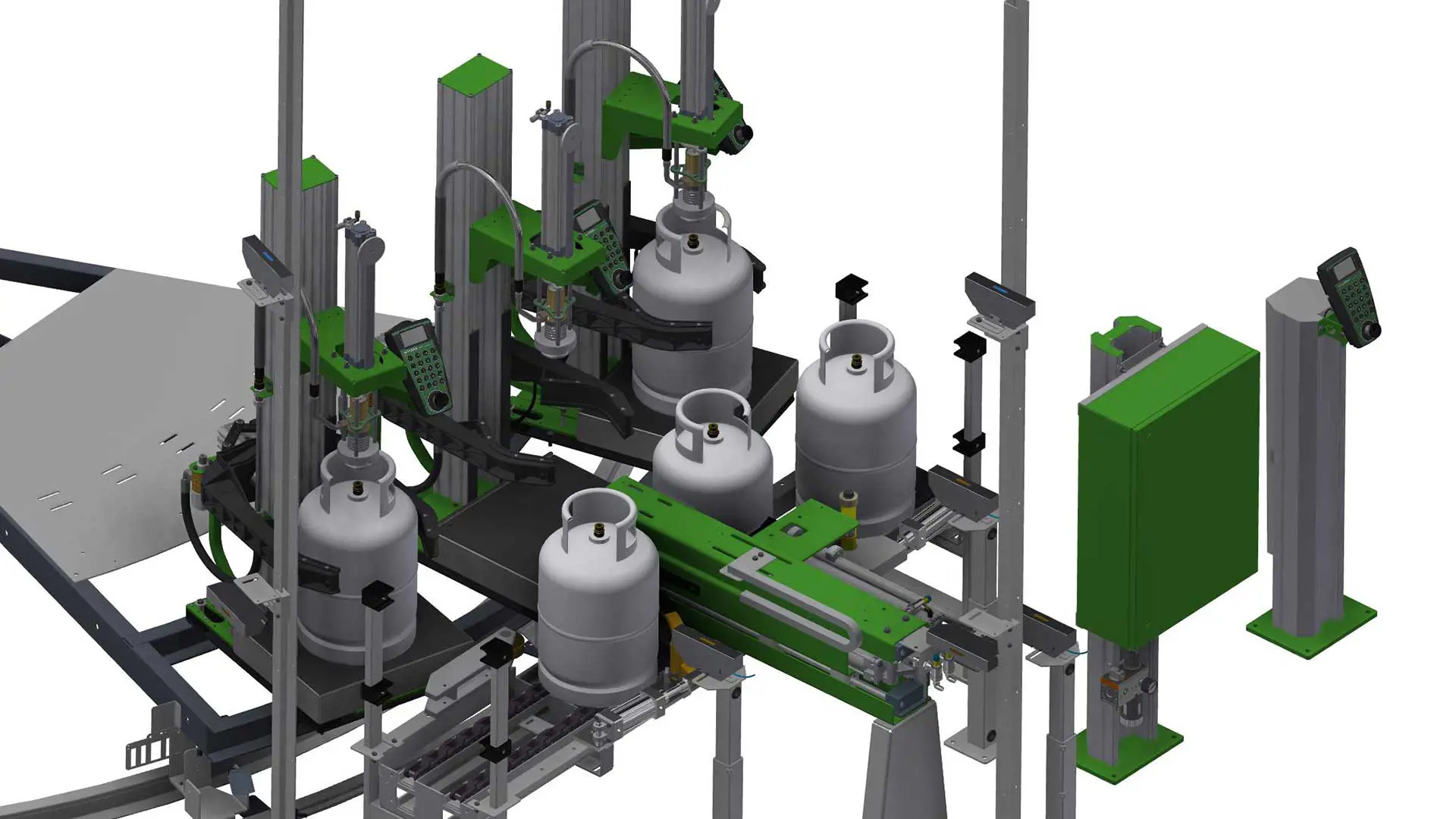

Filling equipment

The fully automatic electronically controlled carousel inlet/outlet unit TIE is designed to transfer LPG cylinders from a chain conveyor to a filling (or pressure testing) carousel, and transfer them back to the chain conveyor. The TIE is installed in a chain conveyor that runs tangentially in relation to the carousel, and requires a minimum of space for the introduction/ejection operations.

The TIE is easily adaptable for left or right orientation, so it can be used on carousels rotating clockwise or counterclockwise.

Benefits

Maximum safety level

- Increased cylinder life due to elimination of typical cylinder handling damages

- An anti-jamming control ensures that the inlet will not activate (to introduce a cylinder) unless a cylinder is available at the inlet, and the filling machine is ready (e.g. no cylinder on the platform, filling head is up) and positioned in front of the inlet

- The anti-jamming control also ensures that the outlet will not activate (to eject a cylinder) unless there is no cylinder accumulation on the outlet conveyor, and the filling machine is ready (e.g. cylinder is on the platform, filling head is up) and positioned in front of the outlet

- Cylinder introduction/ejection with clamping unit for tall cylinders and cylinders with damaged foot rings to prevent toppling

Maximum production uptime

- Automatic predictive and preventive maintenance alerts with MAKEEN Energy’s Industry 4.0 Digital Solution to avoid breakdowns (optional)

- Automatic operation stops (e.g. low compressed air pressure) prevent process errors and assist in quick restarting

Optimised production

- Remote supervision with MAKEEN Energy’s Industry 4.0 Digital Solution for production optimisation

- Fully automatic transfer of all cylinders (eliminates human handling)

MAKEEN Connect

This unit is compatible with MAKEEN Energy's Industry 4.0 Digital Solution, which enables data capturing of the process for remote supervision, performance optimisation, and predictive/preventive maintenance alerts through e.g. a MAKEEN Energy

cloud solution (optional).